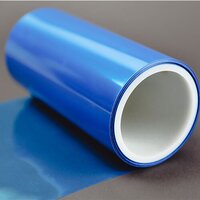

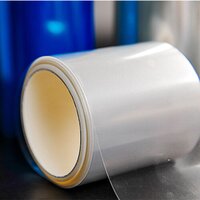

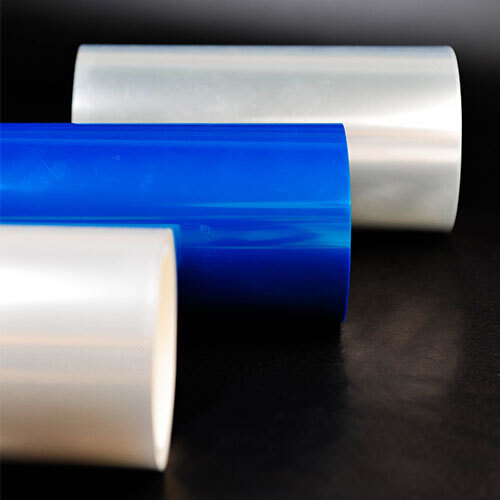

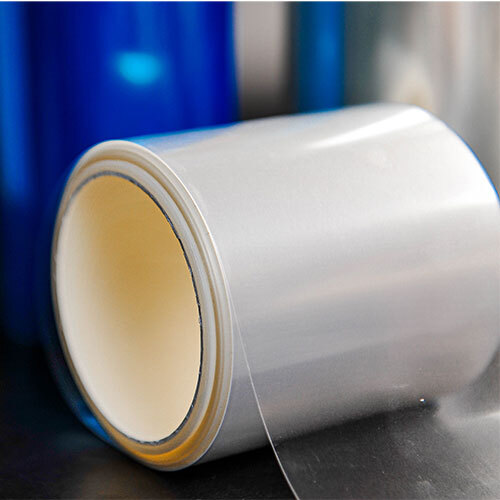

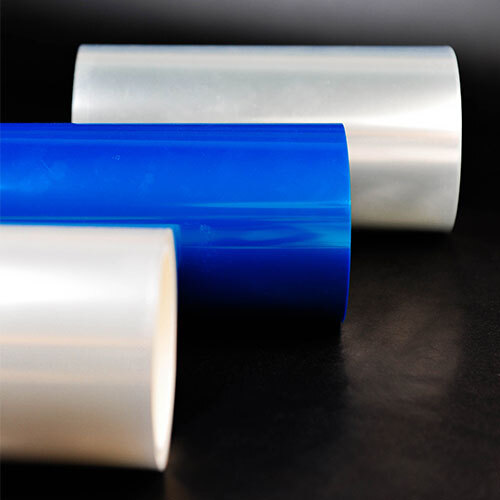

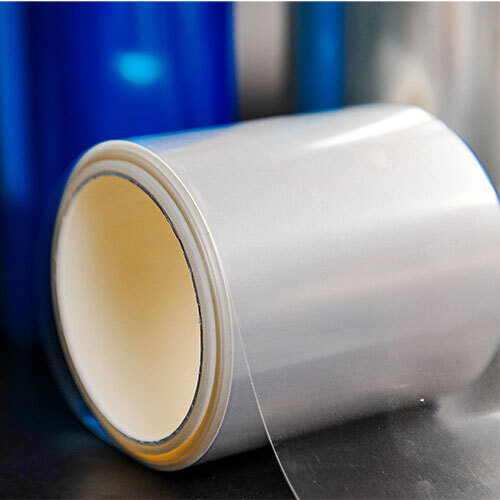

Clear Non-Silicone Release Coating PET Liner Film

Product Details:

- Product Type Plastic Packaging Products

- Material PET

- Dimension (L*W*H) L200m x W1040mm

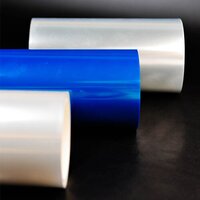

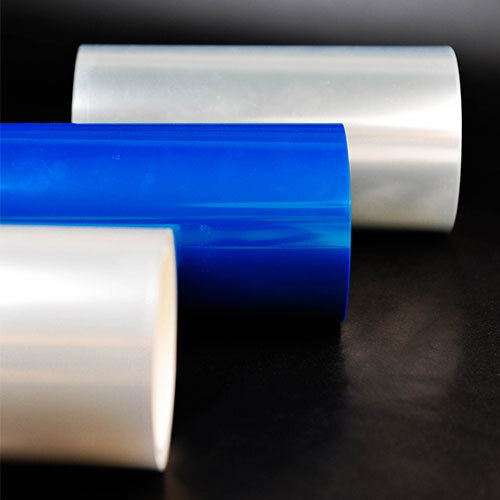

- Color Transparent/ blue/ white

- Click to View more

Clear Non-Silicone Release Coating PET Liner Film Price And Quantity

- 1.00 - 2.00 USD ($)/Square Meter

- 208 Square Meter

Clear Non-Silicone Release Coating PET Liner Film Product Specifications

- Transparent/ blue/ white

- Plastic Packaging Products

- PET

- L200m x W1040mm

Clear Non-Silicone Release Coating PET Liner Film Trade Information

- Taichung Port

- Paypal Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T) Letter of Credit (L/C)

- 3000000 Square Meter Per Month

- 14 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- All India

Product Description

Features:

👉 Low shrinkage

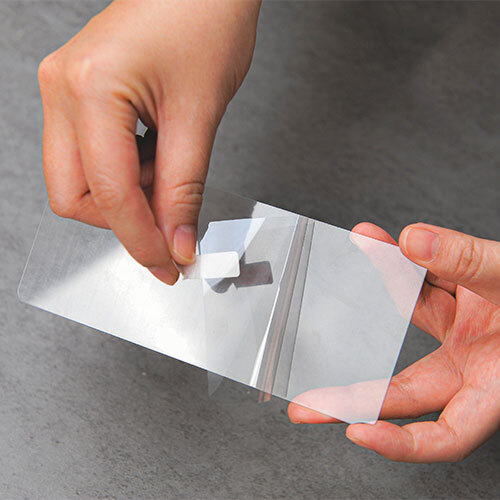

👉 Excellent clarity

👉 Crisp film cutting

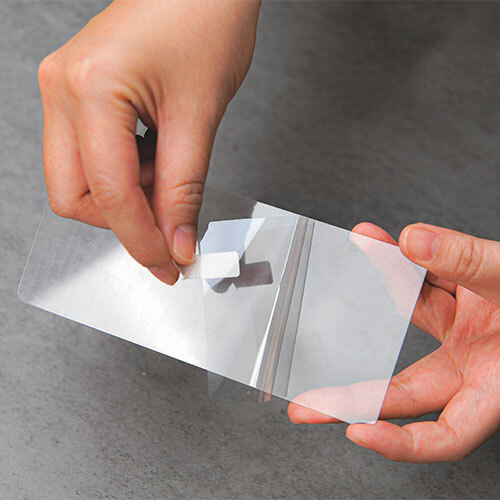

👉 No silicone transfer

👉 Extensive customization

👉 High mechanical strength

👉 Good dimensional stability

👉 Applicable to all PSA tapes

👉 Professional silicone coating process

👉 Individualized solution for each use case scenario

👉 Precise and stable release under all coating processes

👉 Proper transport packaging that protects goods while in transit

Non-Silicone Release Film

HSW special formula eliminates the issue of silicone transfer.

Non-silicone film is suitable for bonding low-adhesive silicone and acrylic adhesives.

Silicone-free film with stable release, uniform coating, and excellent subsequent adhesion.

Color, thickness, release force, width, and length can be custom selected to meet customer needs.

FAQs of PET release films

Q1: Can our release films be customized?

A1: Yes, we can provide the most suitable dimensions based on your specific usage environment.

Q2: What are the available release forces for the release films?

A2: The available release forces are as follows, depending on your needs: 1-5g/ 3-5g/ 5-8g/ 8-12g/ <10g/ 15-25g/ 20-30g.

Q3: Where can release films be used?

A3: Currently, our customers use release films in the following industries: Die-cutting Industry, Thermal pad, electronics industry, adhesive tape industry, printing and packaging industry, and coating industry. However, there are many other potential applications we have yet to explore. If you have requirements outside of these areas, please contact us.